In the competitive oral care industry, product excellence starts long before a toothbrush reaches store shelves. OralGos approaches toothbrush creation with meticulous design, advanced engineering, and a strong commitment to safety and functionality. This process goes beyond manufacturing—it’s precision craftsmanship. Every step, from sculpting ergonomic handles to crafting precision bristles, aims to deliver superior brushing performance. This article guides dental professionals, procurement managers, and private label buyers through the entire OralGos toothbrushes production journey, offering transparent insights into creating high-quality oral hygiene products.

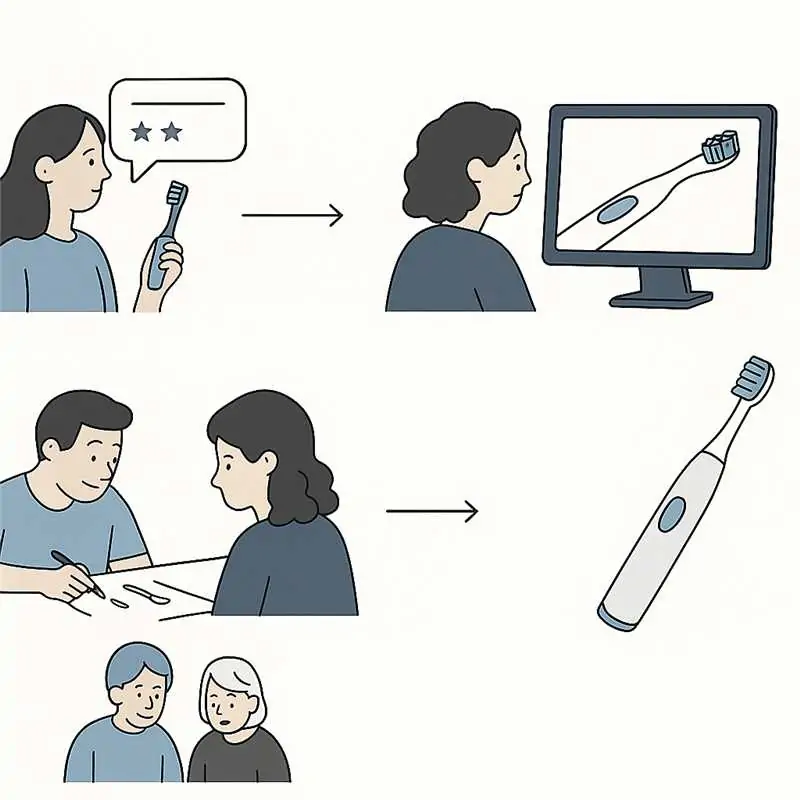

1. User-Driven Design Process

Every successful toothbrush begins with user feedback. OralGos actively collects insights from dental professionals, hygienists, and end-users worldwide. Complaints about slippery grips, ineffective brushing patterns, or harsh bristles directly influence product concepts.

Using CAD (Computer-Aided Design) software, the design team converts these insights into detailed digital models. The team focuses on grip comfort, thumb support, and brush head size. For electric toothbrushes, motor placement and battery configuration also receive careful consideration.

This consumer-first approach ensures each brush feels natural to hold and intuitive to use, regardless of age or oral health condition.

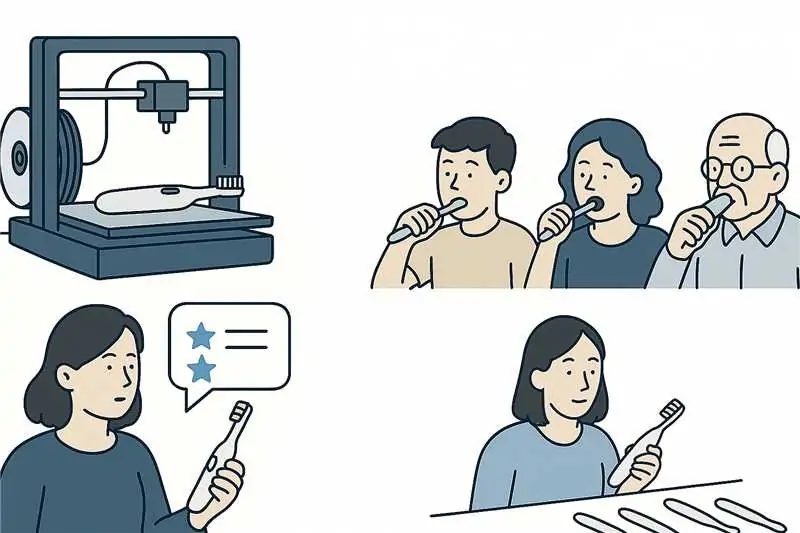

2. How OralGos Toothbrushes Are Prototyped and Tested

After finalizing digital designs, OralGos prints prototypes for hands-on testing. Engineers and users physically evaluate form and function during multi-week trials involving various demographics to collect meaningful feedback.

The team quickly refines designs based on input. Brushes that feel bulky or fail to clean effectively don’t advance. For electric models, engineers test noise levels, motor vibration, and pressure feedback to guarantee comfortable, effective brushing.

The company only moves to production after receiving approval from both users and dental consultants.

3. Premium Material Selection for Safety and Longevity

Material quality directly impacts product performance and user safety. OralGos chooses BPA-free, medical-grade plastic for all handles. The brand uses high-quality nylon for bristles, with specialized options like feathered or charcoal-infused filaments for sensitive teeth and gums.

The procurement team selects rechargeable batteries and waterproof enclosures from REACH/RoHS-certified suppliers. Internal testing verifies component compatibility and long-term reliability.

To address environmental concerns, OralGos also produces eco-friendly models featuring biodegradable handles and recyclable packaging, aligning with global sustainability goals.

4. How OralGos Toothbrushes Are Shaped and Bristled

Technicians start manufacturing by heating plastic pellets and injecting them into high-precision molds, shaping each handle. Quality inspectors check for warping, discoloration, and dimensional accuracy.

Next, automated machines implant bristle clusters into brush heads with sub-millimeter accuracy. Depending on the model, technicians secure bristles using stainless steel staples or thermal bonding. Finally, they polish bristle tips to ensure gentle contact with enamel and gums.

OralGos strictly follows ISO 20126 standards to maintain uniform quality across production batches.

5. Smart Electric Toothbrushes: Designed for Kids and Adults

OralGos also makes smart electric models like the U-Shaped Sonic Toothbrush for Kids and the Oscillation and Vibration Toothbrush for adults. These brushes offer more than just basic cleaning—they’re designed to make brushing easier, safer, and more effective.

The U-Shaped Sonic Toothbrush for Kids has a soft, silicone mouthpiece that fits around a child’s teeth. Kids just bite gently and let the brush do the work. The 360° sonic vibration cleans all sides at once, making brushing fast and fun. This helps young children brush properly, even if they don’t yet have good technique. Parents love it because it saves time and teaches kids healthy habits early on.

For adults, the Oscillation and Vibration Toothbrush offers a deeper clean. It combines fast side-to-side (oscillating) movements with high-frequency vibrations to remove more plaque than regular manual brushes. Users can choose from different cleaning modes—like sensitive, whitening, or deep clean—depending on what they need.

The production team carefully installs motors, batteries, and circuit boards in clean rooms to avoid dust and moisture issues. They test the movement, noise, and brushing strength to make sure each mode works exactly as it should. Each brush gets sealed and waterproofed to handle daily bathroom use without problems.

6. Comprehensive Testing and Quality Assurance

Quality control teams perform extensive inspections on each toothbrush before packaging. They test manual brushes for bristle retention, structural strength, and handle flexibility. Electric models undergo battery performance checks, water resistance tests (IPX7 or higher), and motor durability assessments.

Robotic brushing simulators replicate six months of daily use within 24 hours to accelerate wear testing. Inspectors select random samples for additional endurance tests. Any defect triggers an immediate production line review.

These rigorous checks ensure every OralGos toothbrush performs reliably under real-world conditions.

7. Sanitization and Consumer-Friendly Packaging

Before packaging, the company sterilizes brushes using ultraviolet light to eliminate microbes. Then, they sort brushes into retail units, family packs, or customized private-label boxes.

Packaging combines protection with information. OralGos includes multilingual instructions, QR codes linking to video tutorials, and clear oral care guidance. B2B clients can request co-branded or white-label packaging tailored for online or retail sales.

8. Streamlined Global Logistics

OralGos stores finished products in climate-controlled warehouses, ready for global distribution. The logistics team partners with leading carriers to ensure timely delivery of small and bulk orders.

To enhance service for buyers and distributors, the company integrates real-time tracking and Electronic Data Interchange (EDI) systems, enabling smooth communication and inventory management across the supply chain.

Final Thoughts: Why the OralGos Toothbrushes Production Process Matters

For oral care professionals and retailers, understanding how products are made helps evaluate reliability, safety, and value. Every OralGos toothbrush reflects a culture of precision, accountability, and innovation—from initial sketches to final packaging.

Choosing a manufacturer with a transparent, well-regulated production process reduces risk, strengthens product credibility, and builds customer loyalty.

OralGos doesn’t just produce toothbrushes—it engineers trust with every brush.