The global oral-care industry is rapidly shifting toward customization. For brands that want to stand out, choosing the right OEM Electric Toothbrush manufacturer is crucial.

China is now the top choice for sourcing. This is because of its strong supply chains, low prices, and large production capacity. From concept design to certifications, working with a reliable factory partner ensures product success and long-term business growth.

In this article, we will explore the process from a manufacturer’s view. We will explain how OEM customization works. You will learn what to expect during sampling and quality control. We will also discuss how certifications protect your brand.

Why China Leads in OEM Electric Toothbrush Manufacturing

China’s supply chain advantage lies in integration. Suppliers for motors, batteries, bristles, and molding materials are nearby. This helps lower lead time and costs. For an OEM Electric Toothbrush project, this means quicker product development, simpler customization, and better scalability than other regions.

Factories here also understand the needs of global oral-care brands. You can target premium markets in Europe or entry-level segments in Southeast Asia. Manufacturers can adjust specifications, like brush head density and battery capacity, to meet local needs.

Step 1: Customization Process for OEM Electric Toothbrush Projects

When brands approach a factory for an OEM Electric Toothbrush, the journey usually starts with a concept brief. This can include:

- Design requirements – shape, handle size, and aesthetics.

- Performance needs – sonic vibration speed, oscillation modes, or battery life.

- Target market compliance – CE for Europe, FDA for the U.S., or PSE for Japan.

The manufacturer’s R&D team translates this brief into a technical drawing, followed by 3D modeling and prototype design. Developers may require custom mold development for unique handle shapes or brush head structures.

By working together at this stage, brands make sure the final product matches their goals. This could be a budget-friendly starter toothbrush or a high-end model with many cleaning modes.

Design Requirements for Customized Toothbrushes

Factories carefully evaluate handle ergonomics, waterproof sealing, and material safety. This step ensures the toothbrush meets both functional needs and consumer comfort.

Performance Specs and Battery Options

Different regions demand different performance. Manufacturers can configure sonic vibration levels, oscillation frequencies, and battery life (from 2 weeks to 30 days) to match market expectations.

Step 2: Sampling and Prototyping

Sampling is the bridge between concept and production. Factories typically provide two rounds of samples:

- Functional Samples – These test the motor performance, vibration frequency, and charging system.

- Appearance Samples – These confirm handle design, bristle texture, and packaging.

During sampling, brand owners should pay attention to:

- Ergonomics: Is the handle comfortable for daily use?

- Bristle softness: Does it match the preferences of your target market?

- Waterproofing: Can the toothbrush handle IPX7-level immersion?

This stage often includes private labeling. The factory prints the brand logo on the toothbrush and packaging. This helps buyers see the product as it would appear in stores.

Functional Samples in Electric Toothbrush OEM

Functional prototypes test durability, waterproofing, and vibration consistency, helping brands validate engineering before mass production.

Appearance and Packaging Samples

Appearance models confirm colors, surface texture, and packaging design. This ensures the final product aligns with your brand identity.

Step 3: Quality Control and Production

One of the key advantages of working with an established Chinese factory is robust quality management. Modern facilities adopt ISO 9001 or ISO 13485 systems to guarantee consistency in production.

Typical quality control steps include:

- Incoming material inspection – Motors, batteries, and plastics are tested before entering assembly lines.

- In-line inspections – Supervisors check vibration speed, bristle alignment, and assembly precision during production.

- Final product testing – Random samples undergo drop tests, waterproof checks, and charging cycle evaluations.

By embedding strict QC measures, factories help brands minimize returns and enhance consumer trust.

In-Line QC for Toothbrush Manufacturing

Continuous inspections on the assembly line ensure that vibration motors, batteries, and bristles are within tolerance before shipment.

Final Waterproof and Drop Tests for OEM Models

Each production batch undergoes IPX7 waterproof testing and drop resistance checks, proving durability for global markets.

Step 4: Certifications for Global OEM Electric Toothbrush Markets

Compliance is not optional—it’s the foundation of market entry. A professional OEM Electric Toothbrush manufacturer in China will proactively guide you through certification requirements.

Key certifications include:

- CE / RoHS – Required in Europe for safety and environmental standards.

- FDA listing – Essential for the U.S. oral-care market.

- PSE – Mandatory for Japanese electronics.

- FCC – For wireless charging toothbrushes entering the U.S. market.

Obtaining these certifications not only ensures legal entry into new regions but also signals reliability to distributors and consumers.

CE and RoHS for OEM Electric Toothbrush Exports

These certifications confirm product safety, eco-compliance, and consumer protection across European markets.

FDA and FCC Compliance for OEM Electric Toothbrushes in North America

FDA listing validates oral-care safety in the U.S., while FCC ensures that wireless charging toothbrushes meet electronic regulations.

Building Long-Term Partnerships with OEM Electric Toothbrush Suppliers

The best results come from building partnerships rather than transactional relationships. Leading factories often provide continuous improvement services, suggesting upgrades in motor efficiency, battery capacity, or eco-friendly materials. This ensures that brands remain competitive as consumer expectations evolve.

For example, some manufacturers now integrate biodegradable handles or silver ion bristles into product lines, appealing to sustainability-driven markets. Partnering with a forward-thinking supplier secures your brand’s growth potential.

How to Identify the Right OEM Electric Toothbrush Partner

Here are practical tips for selecting a trustworthy Chinese factory:

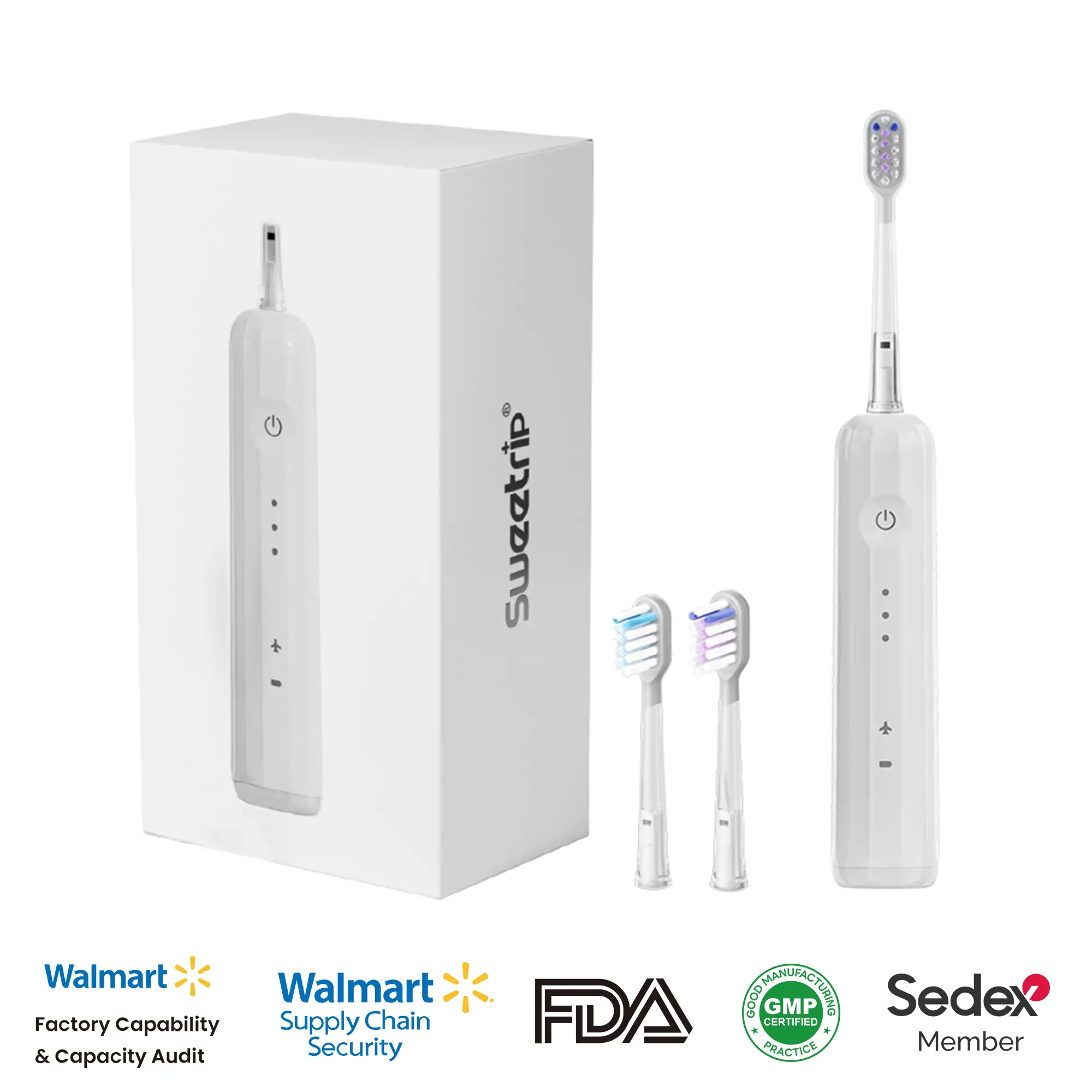

- Check factory audits – Walmart or BSCI-audited factories show proven compliance.

- Review case studies – Ask for examples of toothbrushes they’ve produced for global brands.

- Visit the facility – If possible, tour the production lines to validate capabilities.

- Evaluate communication – A responsive team with clear technical explanations signals professionalism.

By following these steps, you can filter out trading companies and connect directly with manufacturing partners.

Internal and External Resources for OEM Electric Toothbrush Buyers

If you are looking for private-label toothbrushes, check out our OEM services page. You can learn more about design, sampling, and production support there.

To better understand global compliance requirements, you can also consult the European Commission CE guidelines.

Final Thoughts

Finding the best OEM Electric Toothbrush manufacturer in China requires more than just price comparison. Securing a partner that understands customization, ensures strict quality control, and supports your certification journey is essential. By using a smart approach, brands can launch new and dependable oral-care products more quickly. This also helps build trust with consumers around the world.

For new businesses in the oral-care industry, it is important to work with a reliable manufacturer. This partnership is key to success.